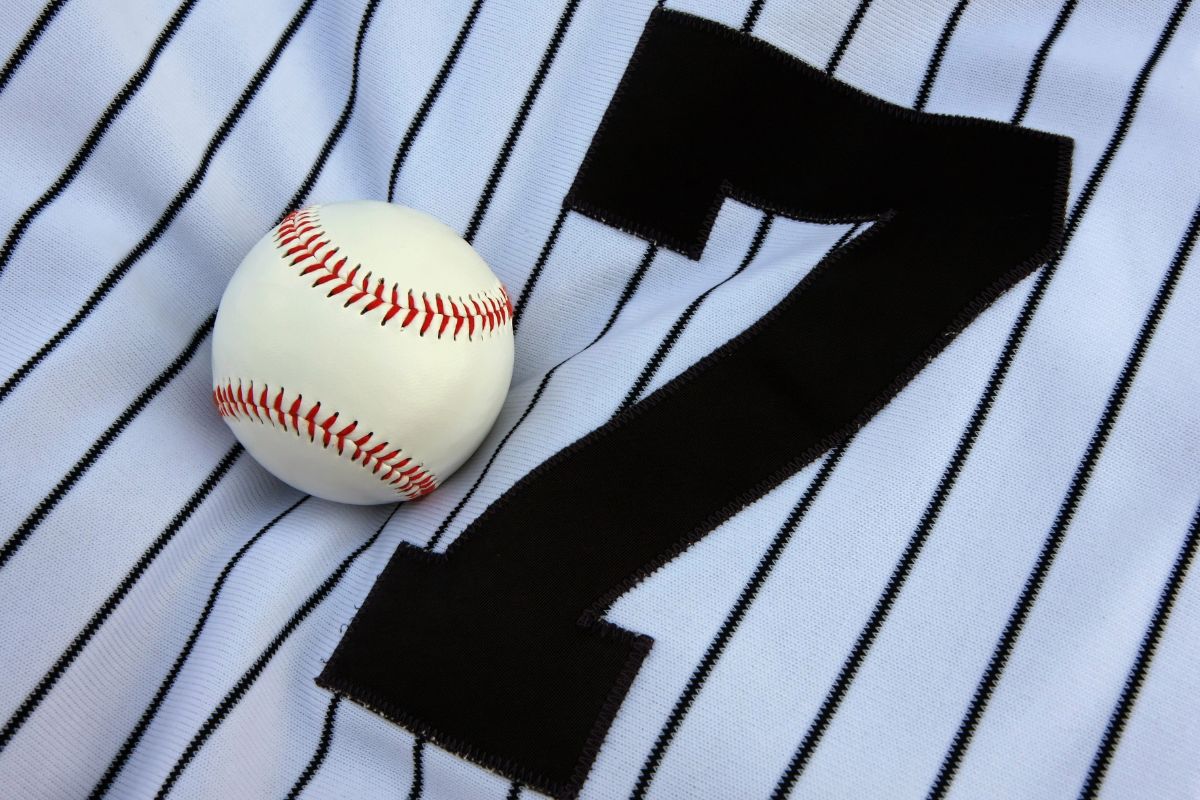

Tackle twill, commonly associated with sports jerseys and uniforms, is a form of decoration that is both aesthetic and durable. This method, also known as appliqué, involves sewing pieces of twill fabric onto a garment. When you see jerseys boasting player numbers and names, there’s a good chance that tackle twill is the technique responsible for those crisp, sturdy designs.

The process requires precision as it entails cutting shapes, letters, or numbers from the twill fabric and then stitching them onto the base material. Tackle twill material is typically a sturdy polyester that, once sewn onto the garment, is resistant to wear and tear. You’ll appreciate this method for its lasting quality, as the stitching around the edges of each piece of fabric helps maintain the integrity of the design even after multiple washes and rugged use.

Especially prevalent in the context of team uniforms and spirit wear, tackle twill offers you an opportunity to showcase bold, large designs that might otherwise be cost-prohibitive or difficult to achieve with standard embroidery. It provides a textured, three-dimensional appearance to apparel, and with its robustness, it has become the go-to method for outfits that require a high level of endurance – benefitting not just athletes but anyone looking for apparel that makes a lasting impression.

Understanding Tackle Twill

In the world of sports apparel, tackle twill has become a mainstay, known for its durability and polished look. It’s a method that brings together the resilience of embroidery with the boldness of fabric appliqué.

Definition and Characteristics

Tackle twill, or appliqué, involves sewing precision-cut pieces of fabric, usually a polyester twill, onto garments. Sports jerseys leverage this technique for its robustness—tackle twill withstands the rigors of physical sports without fraying or fading.

- Durability: Highly resistant to wear and tear

- Aesthetic: Offers a professional, sleek appearance

- Customization: Allows for a high level of detail with intricate designs

Tackle Twill vs. Other Embroidery Methods

Tackle twill stands out from traditional embroidery methods due to its unique combination of fabric and stitching.

- Embroidery: Involves thread-only designs stitched directly into the fabric.

- Tackle Twill: Uses cut fabric designs that are then stitched around the edges.

This method reduces stitch count and often costs less, especially for large designs, making it a go-to for sports teams looking to outfit their players.

Materials and Textiles

Primary materials used in tackle twill include:

- Twill Fabric: Preferred for its crosswise pattern that enhances strength.

- Polyback: Adds stability to the twill before it’s applied.

- PSA Permanent: A type of adhesive that secures the twill, ensuring its position before sewing.

The choice of material contributes to the overall longevity of the embellishments on the sportswear.

History and Evolution

Originally developed for its practicality in sports uniforms, tackle twill has roots that trace back to the traditional techniques of appliqué in sewing. Over time, it has evolved and been perfected, becoming integral to the identity of sports jerseys.

Industry Terminology

Familiarize yourself with key tackle twill terms:

- Appliqué: The technique of applying fabric shapes onto garments.

- Polyback: A backing material that supports the twill during application.

- PSA Permanent: Pressure-Sensitive Adhesive, a type of glue used to bond twill to the garment before it is sewn down permanently.

Understanding these terms will help you discuss tackle twill applications with industry professionals.

Design Aspects of Tackle Twill

In the realm of sports uniforms, your design choices with tackle twill will directly affect the appearance and longevity of the apparel. This method delivers precise lettering and numbers with a professional finish.

Creation Process

To begin, your design is custom cut from polyester twill material. Tough and durable, twill is an ideal choice for sports uniforms where longevity is essential. The twill cutouts—be they letters, numbers, or logos—are then expertly placed on the garment and sewn into position with a tight stitch, typically a zigzag or dotted path, ensuring they adhere firmly and resist wear.

Color and Shape Considerations

Your decisions on color and shape are pivotal as they define your team’s identity. Tackle twill allows for a vibrant display of colors that can withstand the rigors of the sport without fading. It’s important to choose shapes and colors that contrast well with the uniform for maximum visibility and impact.

Selecting Fonts and Characters

When deciding on fonts and characters, consider the readability and aesthetic appeal on your uniforms. The lettering and numbers should be bold and of an appropriate size to be seen from a distance. Tackle twill provides the flexibility to create custom cut designs that reflect your team’s character, allowing for a range of fonts and styles to suit your preference.

Application of Tackle Twill

In the realm of custom garment decoration, you’ll find that tackle twill provides a robust method for adding designs, particularly to sportswear. You’ll see its prominence in the jerseys and uniforms of sports teams because it pairs the aesthetic appeal of embroidery with superior durability.

Sewing Techniques

Beginning with the fundamental approach to applying tackle twill, you need to understand the sewing methods employed. Your design—be it letters, numbers, or custom shapes—is first cut from a polyester twill fabric. Then, it’s sewn onto the garment using specific stitches:

- Zig-Zag Stitch: This is the most common stitch pattern wherein the threads bind the twill to the fabric in a series of back-and-forth stitches.

- Dotted or Straight Stitch: Less common but still used for certain designs, providing a clean and subtle look while ensuring the patch is secure.

Durability and Maintenance

When it comes to longevity of your sportswear, tackle twill stands out. The twill material itself is durable, resisting wear from physical activity and frequent washings. Care for your tackle twill applications by:

- Washing: Gentle cycles and air drying are best to maintain the integrity of the twill.

- Storage: Keep garments in a dry place to prevent any mildew or damage to the threads.

Customization Options

The customization potential with tackle twill is significant. Not only do you have a choice in the color and type of twill patches, but you can also dictate the specific style of your letters, numbers, and designs. Your options include:

- Range of Fonts and Sizes: Tailor your design to fit your team’s brand with an array of font styles and sizes.

- Twill Colors: Select from a wide variety of colors to match your team’s palette or to create contrast for visual impact.

- Placement: Decide where on the jersey or jacket the patches will go for optimal visibility and aesthetic balance.

Tackle twill offers a high-quality, customizable option for elevating the appearance of sports uniforms while promising enduring performance.

Tackle Twill in Athletic Wear

When you consider the athletic wear of your favorite sports teams, the striking visuals are often a combination of vibrant colors and prominent, sturdy designs that withstand the demands of the game. Tackle twill plays a pivotal role in this presentation.

Impact on Sports Uniforms

Your typical sports jersey is built to last, and tackle twill is a significant factor in that durability. On football fields and across various sport courts, twill patches applied to uniforms are commonplace. These pieces of robust polyester twill are cut into shapes or letters and then stitched onto the jersey. This technique ensures the visual elements of a uniform, be it numbers or team emblems, maintain integrity through intense physical activity and frequent laundering. For cheerleading uniforms and varsity jackets, the same approach channels a professional aesthetic that’s both eye-catching and enduring.

Advantages for Teams and Schools Tackle twill presents clear advantages for teams and educational institutions. Here’s how:

- Cost-Effectiveness: Large designs can be more economical due to the lesser amount of stitches compared to full embroidery.

- Longevity: School sports teams don’t have to worry about their uniforms fraying or the lettering coming off. Tackle twill can handle rigorous use without a significant loss in quality.

- Professional Look: High school teams can enjoy the same professional look as major sports teams, which boosts team spirit and unity.

Whether you’re part of a sports team, lead a school club, or manage a sports program at an educational institution, incorporating tackle twill into your athletic uniforms is a decision that balances aesthetics, budget, and functionality.

Commercial Considerations

When evaluating the use of tackle twill, especially for commercial purposes, you need to consider cost effectiveness, production capabilities, and current market trends to ensure both quality and profitability.

Cost and Value Analysis

Tackle twill, employing twill fabric, is recognized for its durability and permanent adherence to garments, making it a wise choice for items like sports jerseys and cheerleading uniforms that undergo frequent use. The upfront cost may be higher than other decoration methods due to the high-quality nature of the fabric lettering, but the longevity of twill patches can provide better value over time.

- Cost comparison:

- Embroidery: Higher stitch counts with intricate designs lead to increased labor and thread use.

- Tackle Twill: Lower stitch counts due to twill fabric application can reduce overall cost for large designs.

Mass Production and Custom Orders

Tackle twill suits both mass production and custom orders. The customization process allows for unique designs on a variety of garments, such as jackets or cheerleading uniforms.

- Production aspects to consider:

- Setup Time: Initial design and setup can be time-consuming but pays off with the ability to replicate designs en masse.

- Efficiency: Once set up, tackle twill applications can be produced relatively quickly, supporting large order fulfillment.

Market Trends and Demand

Your understanding of market trends can inform the use of tackle twill in products. There is a consistent demand for sports twill in both amateur and professional sports sectors due to its association with high-quality sports jerseys.

- Trends: Personalization and long-lasting materials are in high demand in the athletic wear market.

- Demand analysis:

- Popularity in sports jerseys

- Growing interest in nostalgic and retro sporting apparel

By aligning your production of tackle twill with these commercial considerations, you can cater to consumer desires for customization, long-lasting quality, and uphold your brand’s reputation for excellence in garment decoration.

Frequently Asked Questions

This FAQ section addresses common inquiries about tackle twill, highlighting the technique’s application, advantages, cost, material compatibility, maintenance, and comparison to screen printing.

How is tackle twill applied to garments?

Tackle twill is applied by cutting shapes, letters, or designs from twill fabric and then sewing them onto the garment. The edges are usually stitched using a zigzag or dotted stitch to secure the fabric.

What are the benefits of using tackle twill for jerseys?

Using tackle twill for jerseys offers durability and a professional appearance. The twill material can withstand rigorous activity and frequent washing, making it suitable for sports jerseys and uniforms.

How do the costs compare between tackle twill and traditional embroidery?

Tackle twill tends to be less expensive than traditional embroidery, especially for larger designs. It requires less thread and time to sew each letter or design, which can reduce the overall cost.

What types of materials are suitable for tackle twill applications?

Polyester twill is most commonly used for tackle twill due to its strength and colorfastness. It can be applied to a range of garment materials including jerseys, sweatshirts, and jackets.

What care is required for items with tackle twill lettering?

Items with tackle twill lettering should be laundered with care. Turning the garment inside out before washing, using cold water, and avoiding harsh detergents will help maintain the twill’s appearance.

How does tackle twill differ from screen printing on fabric?

Tackle twill involves sewing fabric onto garments, creating a textured, raised design, while screen printing applies ink directly onto the fabric, resulting in a flat design. Tackle twill generally lasts longer and stands up better to physical activity than screen printing.