Sublimation printing is a technique that allows you to transfer images onto fabric or other materials using heat-sensitive inks. This process involves turning solid dye particles into gas without going through a liquid stage, hence the name ‘sublimation.’ It begins with printing your desired image onto a special paper, known as sublimation paper, using sublimation ink.

Your design is then placed onto the substrate, such as a polyester garment or a coated ceramic mug, and subjected to high temperatures and pressure using a heat press. The heat transforms the ink into a gaseous state and permanently bonds it with the polyester fibers or coated surface. The result is a vibrant, full-color image that is highly resistant to fading and washing, making sublimation printing popular for creatingcustom apparel, promotional items, and personalized gifts.

Because sublimation printing requires materials that can withstand high temperatures, it’s predominantly used on polyester and polymer-coated substrates. The process produces high-quality, photographic prints with a seamless integration into the product, ensuring that your images don’t peel, crack, or wash away. This makes sublimation printing an excellent choice for your custom printing needs where durability and quality are paramount.

Basics of Sublimation Printing

In this section, you’ll uncover how sublimation printing offers a method to transfer vivid and long-lasting graphics onto various materials using specialized inks and heat.

Definition and Principles

Sublimation printing, also known as dye sublimation, is a printing method where sublimation inks are transferred onto a substrate using heat and pressure. During this process, the sublimation dye transitions between the solid and gas phases without passing through a liquid stage. This method is noted for its ability to producevibrant, full-color images that are permanent and less prone to fading.

Sublimation Process Overview

The sublimation process entails printing your desired image with sublimation inks onto special transfer paper. Once printed, this paper is placed onto the substrate, typically apolyester fabric or a polymer-coated item. Using a heat press, you apply high heat and pressure, causing the inks to sublimate and permeate the fabric or material’s surface. After the heat transfer, the gas reverts to a solid, embedding the color into the item in a way that is resistant to fading and washing.

Materials and Equipment

To perform sublimation printing, you need a dye-sublimation printer specifically designed to handle sublimation inks. These inks are formulated to turn into gas under the influence of heat and pressure, making them distinct from regular inks. You’ll also require sublimation paper, which is specially crafted to hold the sublimation dye in place until it is released. A heat press is another crucial piece of equipment, providing the necessary heat and pressure to transfer the image from paper to your chosen substrate. Common items for sublimation include polyester fabric for apparel andmouse pads or other fabrics with a polymer coating.

Design Creation and Transfer

Sublimation printing allows you to create vibrant, high-definition prints that transfer onto materials using heat-sensitive sublimation inks. This technique gives your designs a durable and vivid appearance when done correctly.

Creating the Design

Before you start with sublimation printing, designing your image is the first crucial step. Utilize graphic software to produce a design that meets your creative vision, keeping in mind that the outcome should be mirror-imaged when transferred. For those just beginning in sublimation printing, it’s essential to understand that the colors on your design often appear muted on sublimation paper but will emerge vibrant once pressed onto the substrate.

Printing and Transferring Methods

When your design is ready to print, you’ll use a specific inkjet printer equipped with sublimation inks. These inks are unique because they transition from a solid directly to a gas when heated, bypassing the liquid phase. You’ll print your design onto sublimation paper designed to hold and release the sublimation inks efficiently. After printing, position the paper onto your chosen material, usually a polymer or polyester surface, and apply heat and pressure using a heat press. This process transforms the inks into gas, which then diffuses into the fabric or material’s fibers.

Transfer Paper and Sublimation Ink

Transfer Paper: Not all paper is suitable for sublimation; you need specific sublimation paper that’s engineered to release the ink when heated. The paper handles the inks in a way that supports a detailed and complete transfer, ensuring your design’s high-definition quality is retained.

Sublimation Ink: The quality of your finished product heavily relies on the sublimation inks used. Once heated by the heat press, these inks turn into gas and permanently bond with the polymer-coated substrate. This results in a transfer that is not only vibrant but also resistant to fading and cracking over time. Sublimation inks provide an extensive color range and are key for prints that pop with color and clarity.

Textiles and Fabrics in Sublimation

In sublimation printing, selecting the right type of textile is crucial for achieving vibrant colors and sharp details. This technique typically requires fabrics that can withstand high heat and have a polymer content conducive to binding with sublimation inks.

Suitable Fabrics for Sublimation

For optimal results, you want to use synthetic fabrics likepolyester or those with a high polyester content. These materials provide a surface that allows for maximum ink absorption, which is essential in sublimation printing. While natural fibers like cotton aren’t generally suitable due to their lack of polymers, there are special coatings that can make them more compatible.

- Polyester fabric: Best for full-color results.

- Poly-blend: Can be used but may result in a more vintage look due to reduced vibrancy.

- Pre-treated fabrics: Available for natural fibers to better accept sublimation inks.

Comparing Polyester to Cotton

Polyester shirts are more suitable for sublimation printing than cotton because they have a high polyester content. This allows the ink to transform into gas and bond with the fabric, resulting in bright and lasting prints.

| Fabric Type | Level of Ink Absorption | Resulting Print Quality |

| Polyester | High | Vibrant and sharp |

| Cotton | Low | Faded and less durable |

Cotton fabrics typically don’t retain the sublimation ink well, which can lead to duller images and a reduction in print longevity.

Fabric Treatment and Preparation

Preparing your fabrics correctly is crucial. Your textile must be pretreated if it’s not already optimized for sublimation. For synthetic fabrics like polyester, this means ensuring they are clean and devoid of coatings that could interfere with ink absorption. Here are some steps:

- Clean the fabric: Remove any residues that might affect print clarity.

- Test the fabric: Conduct a small print test to check for color vibrancy and quality.

- Use a tacky sublimation paper: This will help to prevent ghosting or image blurring during transfer.

It’s also important to remember that the higher the polyester content in the fabric, the better your print’s quality will be, as more dye will be absorbed and less will be left on the paper.

Sublimation on Hard Surfaces

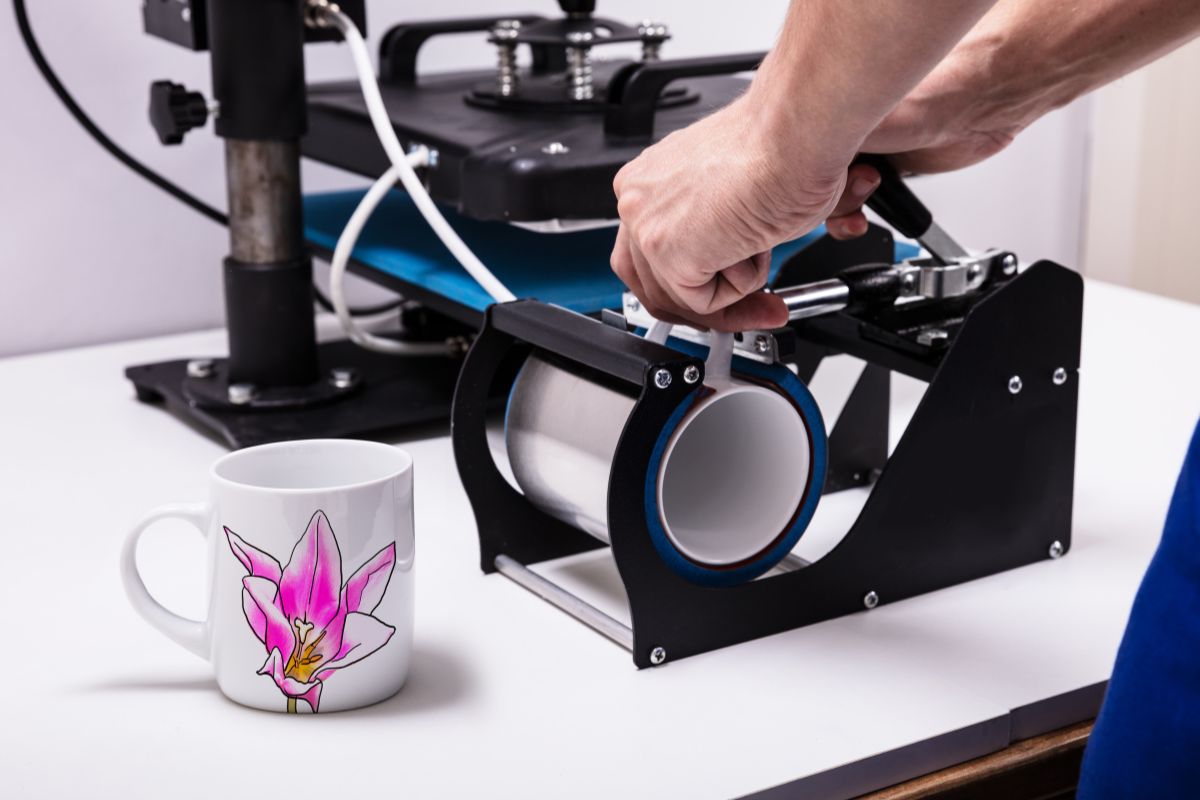

Sublimation printing offers you a creative way to transfer vivid and detailed images onto rigid materials. This method is optimal for crafting durable items, such asmugs and coasters, with a professional and long-lasting finish.

Preparation for Rigid Substrates

When you’re preparing hard surfaces like mugs, signs, or coasters for sublimation, you’ll need to ensure that these items have a special polyester coating. This coating is essential because it allows the sublimation ink to bond effectively, resulting in vibrant images that endure.

- Clean the surface: Start by thoroughly cleaning the item to remove dust, oils, or residues.

- Apply sublimation coating: If you’re working with an item like wood or a puzzle that doesn’t come pre-coated, apply a polyester coating designed for sublimation.

- Secure the transfer: Use heat-resistant tape to fasten the printed sublimation paper onto the item, taking care to smooth out any bubbles or wrinkles.

Sublimation Techniques for Non-Fabric Items

The sublimation process for materials like mouse pads or keychains is slightly different from that used for fabrics. Your goal is to achieve a sharp, high-quality transfer that enhances the item’s functionality and aesthetic appeal.

- Temperature and time: Non-fabric items generally require higher temperatures and longer pressing times. For instance,ceramic mugs might need to be heated at around 400 degrees Fahrenheit for about 4-6 minutes.

- Pressure: It’s crucial to apply the right amount of pressure. Too much can cause the item to crack, while too little might lead to an uneven transfer.

- Testing: Always conduct a test print on a similar material to ensure your settings yield the expected results.

By following specific preparation and technique guidelines for sublimation on hard surfaces, you can create impressive and long-lasting custom items for home décor, personal use, or business marketing.

Advantages of Sublimation Printing

Sublimation printing offers distinct benefits that cater to your need for high-quality, durable, and versatile print output with a considerate eye on environmental impact.

Quality and Durability

Vibrant and Permanent Results: With dye sublimation, the inks transition into a gaseous state and become part of the substrate. This results in prints that are notably vibrant and crisp. Your graphics won’t suffer from cracking or fading, typical of other printing techniques, ensuring a long-lasting and durable finish.

Versatility and Flexibility

All-Over Printing Capability: Sublimation printing empowers your creativity, allowing for all-over printing that other techniques can’t easily match. This flexibility extends to various materials and objects, ensuring that your designs can be applied to a wide range of products from fabrics to ceramics without compromising on quality.

Environmental Perspective

Reduced Environmental Impact: Dye sublimation is generally viewed as an environmentally more responsible printing method. It produces minimal waste and doesn’t require water for dye fixation, unlike traditional textile printing that can have a significant environmental impact. Your choice of sublimation printing reflects your commitment to eco-friendly practices.

Practical Applications

Sublimation printing, a technique that transfers designs onto materials, is used in various sectors due to its durability and high-quality finish. This process is especially favored where vivid colors and long-lasting prints are essential. Here’s how sublimation printing serves practical needs across different industries.

Apparel and Accessories

Sublimation designs are ideal for creating custom apparel such ast-shirts, activewear, and swimwear, as the ink becomes part of the fabric, allowing for a range of dynamic graphics that don’t peel or fade. You’ll find sublimation commonly used for items like leggings and jerseys, where stretchability and breathability of fabrics aren’t compromised.

- Examples:

- Customsports jerseys: Maintains color when stretched.

- Leggings: Offers a comfortable fit with vibrant patterns.

Merchandising and Promotional Items

Sublimation is a go-to method forpromotional items like mugs, pens, and tumblers due to the precision and permanence of the print. The method ensures your business logos and slogans remain visible, despiterepeated use and washes, making it practical for marketing.

- Examples:

- Coffee mugs: Producessmooth, full-color images.

- Pens: Allows fordetailed branding designs.

Home Decor and Art

Sublimation printing enriches home decor pieces and artwork with long-lasting color intensity and clarity. It’s often applied to create decorative signs, cushions, and more. The capability to reproduce complex designs makes it suitable for custom artwork and photographic prints on textiles and rigid substrates.

- Examples:

- Cushions: Features detailed design reproduction.

- Metal signs: Ensures durable, weather-resistant outdoor display.

Choosing the Right Equipment

When embarking on sublimation printing, selecting the right equipment is crucial for both quality and efficiency. Your choices will affect the clarity of your prints, the longevity of the equipment, and the overall satisfaction with your printed products.

Selecting a Sublimation Printer

When choosing a sublimation printer, look for one that can handle high-quality inks and deliver vivid prints. Epson printers are well-known in the industry, often recommended for their reliability and the availability of aftermarket inks. Ensure the printer can accommodate the type of items you plan to print on and that it supports the range of colors you require for your dye-sub designs.

Heat Press Varieties

The heat press is your next critical piece of equipment. They range from clamshell to swing-away models, and each type has its own benefits. The clamshell is more compact and better for beginners, while a swing-away heat press provides more even pressure and heat distribution, which is beneficial when printing on thicker items. You’ll want a heat press that can reach the necessary temperatures for dye-sublimation, ranging around 400°F.

Equipment for Beginners

If you’re a beginner in sublimation printing, you might consider starting with a smaller, more manageable setup. A Cricut machine can be a valuable tool for cutting designs, and a smaller format Epson printer is ideal for starting out before scaling up to larger dye-sub printers. Begin with a basic heat press that is easy to use and focus on learning the intricacies of sublimation printing before investing in more advanced equipment.

Comparison with Other Printing Methods

Sublimation printing stands out with its distinct process of transferring images directly from the ink to the substrate. In this section, you’ll gain an understanding of how it compares with other methods in terms of the transfer process, material compatibility, and quality of output.

Screen vs. Sublimation Printing

Transfer Process:

- Screen Printing: involves pushing ink through mesh screens onto the material.

- Sublimation Printing: transfers ink to a material using heat which turns the ink into gas that bonds with the fabric.

Material Compatibility:

- Screen Printing: works on a variety of materials, but the texture of the material can affect the print’s quality.

- Sublimation Printing: best for polyester and polymer-coated substrates, as it requires heat-sensitive materials.

Pros and Cons:

- Screen Printing Pros: cost-effective for large quantities,durable prints.

- Screen Printing Cons: limited color gradients, lengthy setup.

- Sublimation Printing Pros: vibrant colors, smooth gradients, detail-rich images.

- Sublimation Printing Cons: restricted to specific fabric types, not ideal for dark materials.

Limitations:

- Screen Printing: colors applied one at a time, labor-intensive for complex designs.

- Sublimation Printing: cannot be used on 100% cotton or dark fabrics effectively.

Vinyl vs. Sublimation Printing

Heat Transfer:

- Vinyl Printing: cuts out shapes from colored vinyl and uses heat to transfer to the material.

- Sublimation Printing: heat is crucial for sublimation as it turns the ink directly into gas without becoming liquid.

Material Compatibility:

- Vinyl Printing: suitable for cotton and can be used on dark materials.

- Sublimation Printing: requires polyester or polymer-coated substrates for clear prints.

Pros and Cons:

- Vinyl Printing Pros:vivid colors on any color garment, durability.

- Vinyl Printing Cons: may feel heavy, less breathable, the potential for peeling.

- Sublimation Printing Pros: no feel to the print, breathable, seamless blending of colors.

- Sublimation Printing Cons: prints can fade with excessive UV exposure, limited to light-colored fabrics.

Digital vs. Traditional Printing

Traditional Printing involves methods like screen printing, whileDigital Printing denotes techniques like sublimation or direct-to-garment.

Heat Transfer:

- Traditional Printing: usually does not involve heat in the transfer to the substrate.

- Sublimation Printing (a type of Digital Printing): requires high heat to transfer the ink.

Material Compatibility:

- Traditional Printing: can be applied to a broader range of materials with varied textures.

- Digital Printing: requires smoother materials for high-resolution details.

Pros and Cons:

- Traditional Printing Pros: well-established, suitable for high-volume orders.

- Traditional Printing Cons: longer setup times, not cost-effective for small batches.

- Digital Printing Pros: immediate result with complex, multiple colors, suited for low-volume orders.

- Digital Printing Cons: higher cost per unit for larger orders, limited by fabric type.

Business and Marketing Considerations

In sublimation printing, understanding your market dynamics, cost structures, and customer relationship management is crucial. These elements are the foundation of a profitable sublimation business.

Target Market Analysis

To succeed, you need to identify and understand your target audience. Consider the popularity of sublimation products among various demographics and tailor your offerings. For example, sports teams often require custom jerseys, a niche you could potentially fill.

Cost and Profitability

Sublimation printing can be cost-effective, but initial investments and ongoing costs should be carefully managed. Costs include the sublimation printer, inks, transfer papers, heat press, and substrates. Calculate the cost per item to determine your pricing strategy, ensuring it covers your costs and yields a profit. For small businesses, maintaining low overhead is key.

Building Customer Relationships

Long-term relationships with your customers can lead to repeat business and referrals. Provide excellent customer service and follow-up to ensure satisfaction with the sublimation products. Offering custom designs and accommodating small, personalized orders can distinguish your business in a competitive market.

Challenges and Limitations

Sublimation printing, while innovative, encompasses several challenges and limitations that may affect your production process and output quality.

Common Issues and Troubleshooting

- Nozzle Clogging and Maintenance: Sublimation printers are prone to nozzle clogging, which can result in patchy prints. It’s important to keep the printer’s nozzle clean and perform regular maintenance.

- Color Mismatch: The colors on the final product may differ from the original digital design. Calibration of your sublimation printer and testing on your specific substrates can help manage this issue.

Technique Limitations and Workarounds

- Substrate Restrictions: Sublimation printing is mainly effective on polyester or polymer-coated materials. To work around this, use poly-blended fabrics with a high polyester count for better results.

- Detail Fidelity: Achieving fine details can be challenging. Use high-resolution images and adjust printer settings to maximize the print quality.

Market and Cost Barriers

- Upfront Costs: Sublimation printing equipment and supplies are expensive with significant upfront costs. Consider leasing options or purchasing second-hand equipment to lower initial expenses.

- Volume Restrictions: If you’re looking to print large volumes, sublimation printing may not be the most cost-effective solution due to the cost of ink and the slower process compared to other mass production techniques.

Sublimation Printing Tips and Tricks

To excel in sublimation printing, it’s crucial to focus on the upkeep of your equipment, refining print quality, and exploring creative applications. The following tips and tricks will serve as a guide to elevate your sublimation projects, whether you’re working with home decor or crafting sublimation blanks.

Maintenance and Care

Regular maintenance of your heat presses is essential for long-lasting performance. Ensure you clean the plates after use to prevent any buildup of dye-sub residue. For sublimation dyes, store them in a cool, dry place away from direct sunlight to maintain their vibrancy, with colors like magenta and yellow being particularly prone to degradation if not cared for properly.

- Sublimation Blanks: Always use a lint roller to remove any dust or fibers, as these can cause imperfections in your final product.

- Heat Presses: Check the pressure and temperature accuracy monthly to ensure consistent quality.

Optimizing Print Quality

Achieving high print quality in dye sublimation printing hinges on several factors:

- Color Management: Regularly calibrate your printer for color accuracy, making sure that magenta, yellow, and the full spectrum reproduce faithfully on your substrates.

- Transfer Process: Use high-quality sublimation transfers or infusible ink to ensure clean, sharp, and bright images. The correct temperature and pressure on your heat press are critical.

- Always conduct a test print on a similar material to gauge color accuracy.

- Use the correct ICC profile for your printer to ensure that colors like magenta and yellow are vivid and true to tone.

Innovative Techniques and Ideas

Explore new possibilities with dye-sublimation by incorporating your unique touch to products:

- Home Decor: Try unexpected substrates to offer one-of-a-kind pieces, such as personalized clocks or custom kitchen backsplashes.

- Volume: For larger projects or increased production volume, consider using a calendar press to enhance efficiency and speed.

- For sublimation for beginners, start with simple projects like small home decor items before advancing to more complex pieces.

- Mixing sublimation dyes creatively can result in interesting color effects and gradients, providing your products with a distinctive flair.

By adhering to these tips and practices, you can maintain your equipment in top condition, produce prints of exceptional quality, and continue to develop innovative sublimation products.

Frequently Asked Questions

Discover the intricacies of sublimation printing through these commonly asked questions, gaining a deeper understanding of its applications on various materials and the required equipment.

How does sublimation printing work on different materials such as fabric, paper, and mugs?

Sublimation printing involves converting solid dye particles into gas using heat and pressure, which then bond to polymer-coated materials. For fabrics, it requires synthetic fibers like polyester to ensure longevity. On paper, special sublimation transfer paper is used to transfer designs, whereascoated ceramic or metal mugs provide the necessary surface for the sublimation inks to be infused.

Can standard inkjet printers be converted to perform sublimation printing, or is a specialized printer required?

Yes, standard inkjet printers can be converted for sublimation printing by replacing the regular ink with sublimation ink and using compatible sublimation transfer paper. However, for optimal results and to ensure the longevity of your printer, a specialized sublimation printer is recommended as they are specifically designed to handle the sublimation inks’ properties.

What distinguishes sublimation printing from traditional printing methods?

Sublimation printing differs from traditional printing methods by the way the ink bonds to the material. Rather than laying on top of the substrate, sublimation ink becomes part of the substrate itself, resulting in a more durable and high-definition finish. This process eliminates the risk of the design peeling, fading, or cracking over time.

Why is sublimation printing preferred for certain types of products and applications?

Sublimation printing is preferred for products that demand high-quality, permanent images such as sportswear, promotional products, and customized gifts. This method allows for vibrant, full-color, all-over designs with a professional finish that does not impede the material’s feel or breathability, making it ideal for intricate patterns and photographs.

In what ways does sublimation printing differ from heat transfer techniques?

Sublimation printing differs from traditional heat transfer techniques in that it dyes the fabric at a molecular level, leaving no additional texture or layer. Heat transfer typically involves applying a heat-activated adhesive with the design on top, which can be felt as an extra layer and may crack or peel over time. Sublimation, however, results in a completely smooth finish.

What are the necessary steps for successfully completing a sublimation printing project using a Cricut machine?

To complete a sublimation project with a Cricut machine, you’ll need to print your design onto sublimation paper with sublimation ink, cut the design using the Cricut cutter, and apply it to your sublimation-friendly material using a heat press. Ensure that your material is suitable for sublimation and follow specific temperature and timing instructions for the best results.