Are you searching for ways to create standout custom tee shirts that perfectly capture your vision for a particular event? This post strips back the complexity, guiding customers through selecting the ideal tee, carving out original graphics, and maneuvering the printing process with ease.

Readers will discover the intricacies of different printing techniques, understand how to prepare their own shirt design for print, and learn about crucial post-printing practices to ensure the longevity of their custom apparel.

Table of contents

- Step by step: Printing Custom T-Shirts for Any Occasion

- Understanding Custom T-Shirt Printing Techniques

- Selecting the Right T-Shirt for Your Occasion

- Designing Your Custom T-Shirt Artwork

- Preparing Your Design for Printing

- Step-by-Step Guide to Printing Your T-Shirts

- Post-Printing Care and Maintenance

- Conclusion

Whether it’s a small gathering or a large-scale event, this guide ensures that finding “custom shirts near me” results in apparel that’s both strikingly unique and crafted to last.

Step by step: Printing Custom T-Shirts for Any Occasion

| Step | Description |

|---|

| 1. Choose a Design | Create or select a design that suits the occasion (e.g., birthdays, weddings, corporate events, or holidays). |

| 2. Select the T-Shirt Type | Decide on the fabric, style (crew neck, V-neck), and color based on the event and target audience. |

| 3. Pick a Printing Method | Choose between screen printing, direct-to-garment (DTG), heat transfer, or sublimation based on your needs. |

| 4. Find a Print Provider | Use a print-on-demand service like Printify, Printful, or a local print shop for quality and cost-effective printing. |

| 5. Upload Your Design | Upload the design to the print provider’s platform, ensuring it meets size and quality requirements. |

| 6. Place a Test Order | Order a sample to check the print quality, colors, and fabric feel before printing in bulk. |

| 7. Set Your Pricing | Determine the selling price by factoring in production costs, design complexity, and desired profit margin. |

| 8. Market Your T-Shirts | Promote your custom T-shirts on social media, via email campaigns, or through event-specific promotions. |

| 9. Fulfill Orders | Use a reliable fulfillment service or handle packaging and shipping yourself for timely delivery. |

| 10. Gather Feedback | Collect customer feedback to improve future designs and printing quality, enhancing your offerings. |

Understanding Custom T-Shirt Printing Techniques

Choosing the right printing technique for custom tees hinges on factors like price, the fabric used such as cotton, and the urgency of the order. Screen printing offers a timeless approach for bulk orders, while direct-to-garment printing shines in delivering high-resolution images on tank tops or soft cotton shirts.

Heat transfer printing, on the other hand, is optimal for rush orders with intricate designs. This section provides insight into when and why to utilize each method.

Exploring Screen Printing Methods

Screen printing, a preferred method for tshirt printing, excels in producing vibrant, durable prints for a range of garments, including shirts and hoodies.

A key advantage lies in the technique’s ability to replicate a design repeatedly without sacrificing quality, making it ideal for brands that require consistent imagery across numerous items. This method involves transferring ink through stenciled mesh screens, creating sharp, clean graphics that endure wash after wash.

For entrepreneurs and designers utilizing a shirt design maker, screen printing offers a way to customize your own shirt with complex layers and a variety of colors.

Although setting up for screen printing might involve more preparations compared to other techniques, the resultant brand imagery on custom apparel is often superior in texture and detail, especially for orders with a high quantity, solidifying its standing in the realm of print on demand services.

Advantages of Direct-to-Garment Printing

Direct-to-garment printing revolutionizes the custom tshirt design process for both entrepreneurs aiming for a Gildan softstyle tee or a casual jersey fit. This method garners appreciation for its high fidelity to detail, allowing limitless color variations at a resolution that stands out on any sleeve length.

Unlike screen printing near me inquiries that lead to traditional print shops, direct-to-garment is readily accessible via online platforms, offering a responsive solution to modern print needs.

The technique notably excels for smaller batch orders, where the design intricacy might be cost-prohibitive using conventional methods. Direct-to-garment printing injects ink directly into the fabric, thereby delivering a soft, breathable finish ideal for personalized apparel.

Print on demand companies find this method instrumental in fulfilling custom orders efficiently, achieving vibrant, photographic-quality imagery that attracts a discerning clientele.

When to Use Heat Transfer Printing

Heat transfer printing is often the top selection for custom ink shirts that demand precise color matching or a design requiring a full-color spectrum.

This technique excels over screen printing when there’s a need for high levels of detail on a low volume order, offering a cost-effective alternative for designing your own shirt.

Ideal for events like family reunions or small-scale promotional activities, heat transfer allows individuals to create personalized custom t-shirts with vibrant, photo-quality graphics.

One of the standout attributes of heat transfer printing is its swift turnaround time, greatly benefiting projects with tight deadlines.

By applying heat and pressure, the design is transferred onto the fabric, ensuring that the final product bears no compromise on color intensity or complexity of the image.

Proficient for small runs where screen printing may not be viable, this method provides the flexibility to print unique designs on various garment types:

- Custom t-shirts for special occasions

- Personalized jerseys for sports teams

- Corporate apparel with detailed logos

Selecting the Right T-Shirt for Your Occasion

| Occasion | T-Shirt Type | Fabric/Material | Design Considerations | Best for |

|---|---|---|---|---|

| Casual Everyday Wear | Basic Tee or Crew Neck | Cotton, Cotton Blends | Simple designs, logos, or minimalist graphics | Daily wear, streetwear, brand promo |

| Sports and Activewear | Performance or Sports Tee | Moisture-wicking fabric (Polyester, Spandex) | Bold graphics, sports team logos, athletic-themed designs | Sports enthusiasts, gym-goers |

| Summer/Beachwear | Tank Tops or V-Neck Tees | Light Cotton, Linen, Rayon | Tropical patterns, beach-related graphics | Hot weather, vacations, beach trips |

| Special Events (Weddings, Birthdays) | Custom Event Tees (Personalized) | Cotton, Polyester | Custom text, dates, and personalized graphics | Weddings, birthdays, family reunions |

| Music Festivals & Concerts | Band/Graphic Tees | Soft Cotton or Blended Fabrics | Band logos, concert dates, artistic designs | Concert goers, music lovers |

| Eco-Friendly/Fair Trade | Organic Cotton Tees | Organic Cotton, Recycled Materials | Nature-themed designs, slogans promoting sustainability | Eco-conscious buyers, green initiatives |

| Winter & Fall Seasons | Long Sleeve or Hoodie | Cotton, Fleece, or Blends | Cozy designs, graphic prints, quotes | Cold weather, layering, cozy looks |

| Holiday & Seasonal | Holiday Graphic Tees | Cotton, Polyester, Blends | Festive designs, holiday-specific graphics (Christmas, Halloween) | Christmas, Halloween, national holidays |

| Corporate/Workwear | Polo Shirts or Button-Down Tees | Cotton or Blended Fabrics | Clean, professional logos or simple text | Corporate branding, team uniforms |

| Creative & Artistic Designs | Artistic Print Tees | Premium Cotton or Tri-blends | Artistic, intricate, or custom illustrations | Art lovers, creative individuals |

Selecting an appropriate t-shirt for custom printing involves consideration of fabric types, color selection, and sizing to cater to different audiences.

Choosing resilient fabrics like cotton or polyester ensures that custom tie-dye shirts retain their vibrant hues, while digital printing technology brings detailed images to life with exceptional clarity.

The company places a high priority on customer service, guiding clients through the process of matching their design’s color palette and selecting sizes to suit diverse groups. Each subsequent section delves into these considerations, highlighting their significance in creating custom t-shirts for any occasion.

Choosing Fabric Types Suitable for Printing

When selecting fabric types for tee printing, it is paramount to consider how the material will interact with the printing process. For a durable design, fabrics like those offered by Hanes provide a sturdy canvas for both screen printing and embroidery, catering to varied customer needs.

Materials that have a smooth, tight weave ensure high-quality prints and are suited for 24 hour shirt printing services, where speed and efficiency are essential.

In cases where large quantity orders are required, choosing the right fabric becomes critical for maintaining consistency across all items. A blend of cotton and synthetic fibers can offer the resilience needed for intricate designs and multiple washes.

This consideration is particularly relevant for businesses that rely on uniform branding, where the sharpness of the printed logo or image is a direct reflection of the company’s image.

Picking the Perfect Color to Match Your Design

The choice of shirt color is pivotal for any design, particularly when incorporating a logo. A custom shirt maker understands that the contrast between shirt and design ensures visibility and impact.

When clients order custom shirts, professionals offer guidance on selecting colors that will make their logos pop, while ensuring that the nuances of the design are not lost in the amalgamation of hues.

For those seeking a more corporate look with custom polo shirts, the emphasis on elegance requires a more subdued palette that complements the brand identity.

Selecting the ideal shirt color can enhance the perceived value of the apparel, and experienced providers of custom printing services adeptly navigate this process to deliver results that blend design integrity with the client’s vision.

Sizing Options for Different Audiences

Ensuring that custom-printed attire suits a broad demographic is critical, which is why a satisfaction guarantee often accompanies tee shirt printing services.

Whether the preference is a snug crew neck or a more relaxed fit for custom long sleeve shirts, the objective remains the same: to offer a range of sizes that cater to every body type, building trust through inclusivity and a commitment to client satisfaction.

When dealing with clothing diversity, the print on demand company operates with a profound understanding that one size does not fit all. Accurate sizing options are imperative in conveying a brand’s attention to detail, leading to enhanced customer experiences.

Thus, precise measurements and clear sizing charts form an essential part of pre-print consultations, ensuring each individual feels comfortable and confident in their custom apparel selection.

Designing Your Custom T-Shirt Artwork

Designing custom t-shirt artwork demands a creative fusion of event themes, adept use of design software, and a flair for creating memorable graphics. These elements are essential for producing personalized apparel that not only resonates with the event’s atmosphere but also leaves a lasting impression.

Working with a print on demand provider, designers learn to infuse designs with ink that captures the essence of the occasion. The following guidance focuses on transforming blank canvases into expressive garments reflective of the event’s spirit, providing invaluable tips and insights into the art of t-shirt design.

Incorporating Event Themes Into Your Design

Incorporating event themes into t-shirt designs is crucial for creating visually cohesive and contextually relevant apparel. When working on custom t-shirts for events like conferences or charity runs, using symbols, color schemes, and fonts that reflect the core message and branding can elevate the overall impact.

The print on demand company’s expertise lies in guiding clients through the fusion of these elements to produce garments that not only embody the event’s spirit but also reinforce its identity.

For instance, a music festival t-shirt might draw on vibrant graphics and bold text that resonate with the energy of live performances, while t-shirts for a corporate team-building retreat might employ more subdued colors and structured designs to align with professional themes.

The process of translating the essence of an occasion into tangible designs requires skillful application of design principles, ensuring that every garment effectively communicates its intended message:

| Event Type | Design Approach | Color Palette | Font Selection |

|---|---|---|---|

| Music Festival | Dynamic graphics, energetic motifs | Bright, bold | Casual, expressive |

| Corporate Retreat | Clean lines, minimalist icons | Neutral, muted | Professional, readable |

Using Design Software Effectively

Mastering design software is a fundamental skill for creating impactful custom t-shirt graphics. Print on demand companies often recommend platforms like Adobe Illustrator or Photoshop due to their robust toolsets that accommodate intricate designs and color management.

Users benefit from vector-based software for crisp, scalable graphics ensuring printed artwork looks as intended, whether on small tank tops or large sweatshirts.

For newcomers seeking to design custom shirts, utilizing templates and user-friendly interfaces of design software can streamline the creation process.

Tools that allow for easy manipulation of text, shapes, and layers contribute to a design that’s both aesthetically pleasing and print-ready. Effective use of design software can transform a basic concept into professional-looking apparel, mirroring the creator’s original vision:

- Templates guide the layout and ensure proper dimensions

- Layering features enable complex designs with multiple elements

- Color-picking tools help match the printed ink to the design accurately

Tips for Creating Memorable Graphics

Creating memorable graphics for custom t-shirts necessitates an understanding of the brand’s message along with a recognition of the audience’s preferences and expectations. It requires a graphic that goes beyond mere aesthetics, embedding itself in the viewer’s memory.

This can be achieved by incorporating unique, eye-catching elements that resonate with the viewers while ensuring that the design aligns seamlessly with the message it intends to convey.

When designing graphics for custom t-shirts, simplicity often leads to the most enduring impact. A clear, focused image with a concise message tends to stand out more than a cluttered and complicated design.

Utilizing contrasting colors and legible typography helps make the design readily identifiable from a distance, which is particularly effective for events or brand promotions where visibility is key.

Preparing Your Design for Printing

Transitioning from design to print demands keen attention to detail. This involves understanding resolution and file formats critical for maintaining design integrity, considering colors that accurately reflect your vision across various printing methods, and finalizing artwork to ensure the highest quality results.

Upcoming sections will guide you through these essential steps, equipping you with the knowledge to achieve impeccably printed custom t-shirts for any occasion.

Understanding Resolution and File Formats

Initiating the printing process requires designers to provide images in the correct resolution and file format to ensure clarity and fidelity of the final print.

High-resolution images are paramount; typically, a resolution of 300 dpi (dots per inch) is considered ideal for a sharp, detailed transfer onto t-shirt fabric. Additionally, file formats such as PNG or TIFF are preferred for preserving transparency and ensuring that design elements remain crisp and unaltered when the artwork is scaled for different t-shirt sizes.

The preparatory phase also entails converting the design into a format that is compatible with the chosen printing method. For example, screen printing often requires vector files, which allow for clear separation of colors and clean edges.

Direct-to-garment printing, however, can work well with high-quality raster images that match the printer’s specification. Understanding these nuances and preparing files accordingly is crucial in delivering products that meet and exceed customer expectations.

Color Considerations for Different Printing Methods

Selecting appropriate colors for respective printing methods is crucial for the accuracy and vibrancy of custom t-shirts. Screen printing requires distinct color separation, which can affect design choices, whereas direct-to-garment printing supports full-color images but may demand careful consideration of the ink’s interaction with fabric color.

Understanding these subtleties is key for print on demand companies to deliver products that faithfully represent the original artwork envisioned by the client.

Different printing techniques can also vary in their capacity to reproduce specific shades and gradations, potentially altering the final appearance of the design.

For instance, heat transfer printing can vividly depict a wide spectrum of colors, including gradients, but it’s essential to adjust the colors in the design file to compensate for any discrepancies that might occur during the heat pressing process.

This level of detail serves print on demand businesses in ensuring the highest quality output that satisfies the nuanced color requirements of their clientele.

Finalizing Your Artwork for Best Results

Finalizing your artwork for best results is a critical step to ensure the design on your custom t-shirt is sharp, vibrant, and durable. Before sending the design to the print on demand company, double-check that all visual elements are clear, and text is legible.

Proofreading for errors is vital; any typo or unnoticed mistake will be replicated across the product line, potentially affecting the brand’s professionalism.

It’s essential to consider the nuances of the chosen print method when finalizing artwork. For screen printing, the artwork must be broken down into individual color layers, while direct-to-garment printing requires high-resolution files to maintain the integrity of intricate details.

Sharing your design in the correct file format with the print provider optimizes the print quality, leading to consistently excellent results across all custom-printed t-shirts, irrespective of the occasion.

Step-by-Step Guide to Printing Your T-Shirts

| Step | Action | Method |

|---|---|---|

| 1. Prepare Design | Create a high-resolution design (300 DPI). | Use tools like Photoshop, Illustrator. |

| 2. Choose Printing Method | Select a printing method based on design & quantity. | Options: Screen Printing, DTG, Heat Transfer, Sublimation. |

| 3. Select T-Shirt | Choose the t-shirt material and style. | Consider fabric (cotton, polyester) & color. |

| 4. Print Design | Print the design onto the t-shirt. | Use the selected method (e.g., screen print, DTG, heat press). |

| 5. Cure the Ink | Set the design with heat to make it durable. | Use heat press or conveyor dryer (depends on method). |

| 6. Inspect Quality | Check for vibrant colors, correct placement. | Ensure no smudges or misprints. |

| 7. Package & Ship | Fold and pack the t-shirt, then ship. | Use protective packaging for shipping. |

Embarking on the journey to produce custom t-shirts for any event involves more than just a creative design. Setting up your printing equipment correctly lays the foundation for a successful print job.

Next, the application of the design onto the shirt requires precision to ensure the artwork is accurately rendered.

Finally, mastering curing and drying techniques is crucial for enhancing the durability of the print, providing wearers with a long-lasting product. Together, these steps weave the tapestry of quality in custom t-shirt printing, promising satisfaction for every occasion.

Setting Up Your Printing Equipment

Setting up printing equipment for custom t-shirts begins with ensuring all machinery is calibrated and functioning correctly. This includes checking that the screen printing presses are aligned accurately and that the direct-to-garment printers have clean nozzles for precision. Proper setup not only saves time but also guarantees that each custom t-shirt reflects the high-quality standards expected by clients.

Once the equipment checks are completed, preparing the workspace for efficiency is the next essential step. Organizing inks, screens, and heat presses in accessible layouts minimizes errors and streamlines the production process. Here’s a succinct list of initial tasks to set the stage for a seamless print run:

- Calibrate machines to the specifications required for the specific t-shirt fabric and design.

- Prepare and mix inks or dyes in accordance with the custom design palette.

- Align screens and test print patterns to avoid misprints on the final product.

Applying the Design Onto the Shirt

Applying the design onto the shirt is a precise process that requires attention to detail to ensure the artwork is perfectly aligned and transferred. Once the shirt is properly positioned and secured on the printing platen, the next step is to accurately apply the ink or other medium through the screen or onto the garment directly, as specified by the printing method in use, such as screen printing, direct-to-garment, or heat transfer.

This careful alignment of the design element is crucial for achieving a professional and high-quality finish that meets customer specifications.

The successful application of a design hinges on strict adherence to the prescribed technique and settings. For example, when engaging in screen printing, one must methodically apply pressure to the squeegee to ensure uniform ink distribution.

In contrast, direct-to-garment printing demands precise printer head movement to recreate detailed designs accurately on fabric. Below are the essential steps undertaken during the shirt design application process:

- Position the shirt correctly on the printing platen or press.

- Ensure the screen or printer settings are adjusted for the specific fabric type and design requirements.

- Execute the printing technique meticulously to transfer the design onto the shirt with even coverage and clarity.

Curing and Drying Techniques for Durability

The curing stage in custom t-shirt printing is vital to the durability of the design. Heat setting, a prevalent curing method, involves using a tunnel dryer or heat press to ensure that the ink or vinyl adheres firmly to the fabric and becomes resistant to fading and cracking, essential for custom garments intended for regular wear.

Proper curing ensures the longevity of the design, which ultimately enhances customer satisfaction and brand reputation.

Drying techniques are equally important for securing the print onto the shirt and must be carried out with precision. Depending on the printing method used, air drying or heat setting can provide the necessary bond between the ink and the garment.

For example, direct-to-garment prints often require a heat press to finish, which not only fixes the ink but also gives the print a smooth, professional quality. Applying consistent and appropriate drying methods results in custom t-shirts that maintain their visual appeal over time.

| Printing Method | Curing Technique | Heat Setting Temperature | Drying Time |

|---|---|---|---|

| Screen Printing | Tunnel Dryer | 320°F | 1-3 minutes |

| Direct-to-Garment | Heat Press | 356°F | 30-90 seconds |

| Heat Transfer Printing | Heat Press | 375°F | 20-30 seconds |

Post-Printing Care and Maintenance

After printing, meticulous inspection of the finished t-shirts is imperative for quality assurance. Proper washing instructions enhance the print’s longevity, and secure storage methods ensure the garments remain pristine. This section delves into effective post-printing strategies, from examining the product to maintaining it, providing invaluable advice for preserving the integrity and appearance of custom t-shirts.

Inspecting Your Finished T-Shirts

Upon completion of the printing process, a thorough inspection of the finished t-shirts is essential to ensure they meet the established quality standards. This meticulous review involves examining each garment for print clarity, color accuracy, and any potential defects that may affect the overall appearance and durability. By prioritizing this step, print on demand companies guarantee customer satisfaction by delivering products that fulfill their promise of excellence.

Inspection also extends to the correct application and treatment of the design, verifying that the ink has set appropriately and that the graphic alignment is as specified by the client.

Such attention to detail solidifies the reputation of the print on demand service, as clients come to trust in the consistency and reliability of the products they receive. Reliable inspection processes mitigate the possibility of errors and ensure that every custom t-shirt is ready for distribution or sale:

| Inspection Criteria | Detail | Quality Assurance Check |

|---|---|---|

| Print Clarity | Sharpness and detail of the design. | Visual examination to confirm design precision. |

| Color Accuracy | Faithfulness of printed colors to original design. | Compare against digital mock-up for consistency. |

| Design Treatment | Adherence of ink to fabric, positioning, and finishing. | Assess ink set and design placement for uniformity. |

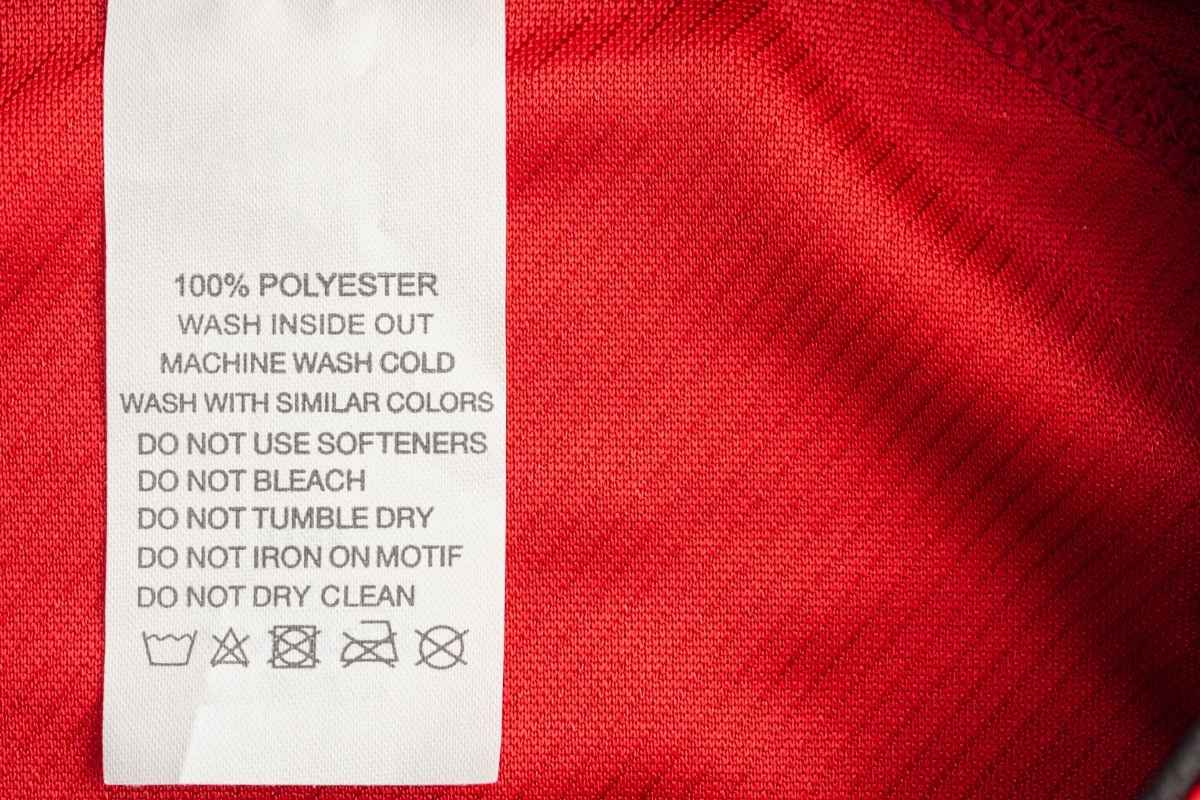

Proper Washing Instructions to Preserve the Print

To ensure the longevity of the print on custom t-shirts, advise customers to wash the garments inside out using cold water. Directing users to avoid bleach and implement a gentle cycle in the washing machine guards the integrity of the ink, maintaining the design’s vibrancy and preventing premature fading.

For drying, recommending that customers tumble dry on a low setting or, preferably, air dry the custom t-shirts is essential. Excessive heat can damage the print, so imparting instructions for proper garment care enhances the quality and durability of the product, fostering customer satisfaction with their personalized apparel.

Storing Your T-Shirts to Prevent Damage

Proper storage of custom t-shirts is essential to prevent the premature deterioration of print quality. Folded neatly and placed in a cool, dry environment, these customized garments maintain their aesthetic appeal for future wear.

The absence of direct sunlight and humidity plays a significant role in preserving the ink from fading or cracking, ensuring that the shirt continues to reflect the brand’s or event’s message with clarity and vitality.

For print on demand companies advising on storage solutions, it is critical to consider fabric composition as well. Storing t-shirts made from cotton blends separately from those with high polyester content can prevent unwanted transfer of dyes and maintain the integrity of individual pieces.

This strategic organization prevents damage from friction or compression, safeguarding the custom prints and extending the lifecycle of each garment.

Conclusion

Choosing the appropriate t-shirt printing technique and fabric type is crucial to ensure that custom designs are vibrant, durable, and fitting for the occasion. Mastering the art and technicalities of design software, alongside an understanding of different fabric textures and inks, is vital for producing high-quality, memorable custom t-shirts.

The steps involved in preparing, printing, and curing designs directly impact the longevity and appearance of the final product, highlighting the importance of precision and expertise in the printing process.

Proper aftercare, including washing, drying, and storage, further guarantees that custom t-shirts retain their quality over time, making them suitable for any event and adding lasting value to the customer’s experience.