When deciding between laser printing andscreen printing, you need to consider what each method offers. Laser printing provides high precision and speed, making it ideal for complex designs on small objects. It’s precise and great for high-volume production, resulting in quicker turnaround times.

Screen printing, on the other hand, excels in producing vibrant and colorful designs. This method works well on various fabrics and materials, delivering strong and vivid prints that are hard to overlook. If you’re aiming for bold, detailed colors, screen printing might be your best bet.

Both methods have their strengths and weaknesses. Laser printing is faster and cleaner, with less setup and maintenance. Screen printing can handle diverse and colorful designs with ease. Understanding the benefits of each will help you choose the right method for your project.

Table of contents

- Fundamentals of Printing Technology

- Process and Mechanisms

- Materials and Equipment Compatibility

- Quality, Precision, and Detailing

- Economic and Production Considerations

- Durability and Longevity

- Color and Design Aspects

- Environmental and Safety Factors

- Advantages and Disadvantages

- Applications and Industry Use

- Frequently Asked Questions

Fundamentals of Printing Technology

The main types ofprinting techniques discussed here are laser printing and screen printing. Each has its own unique method and advantages, suitable for different materials and purposes.

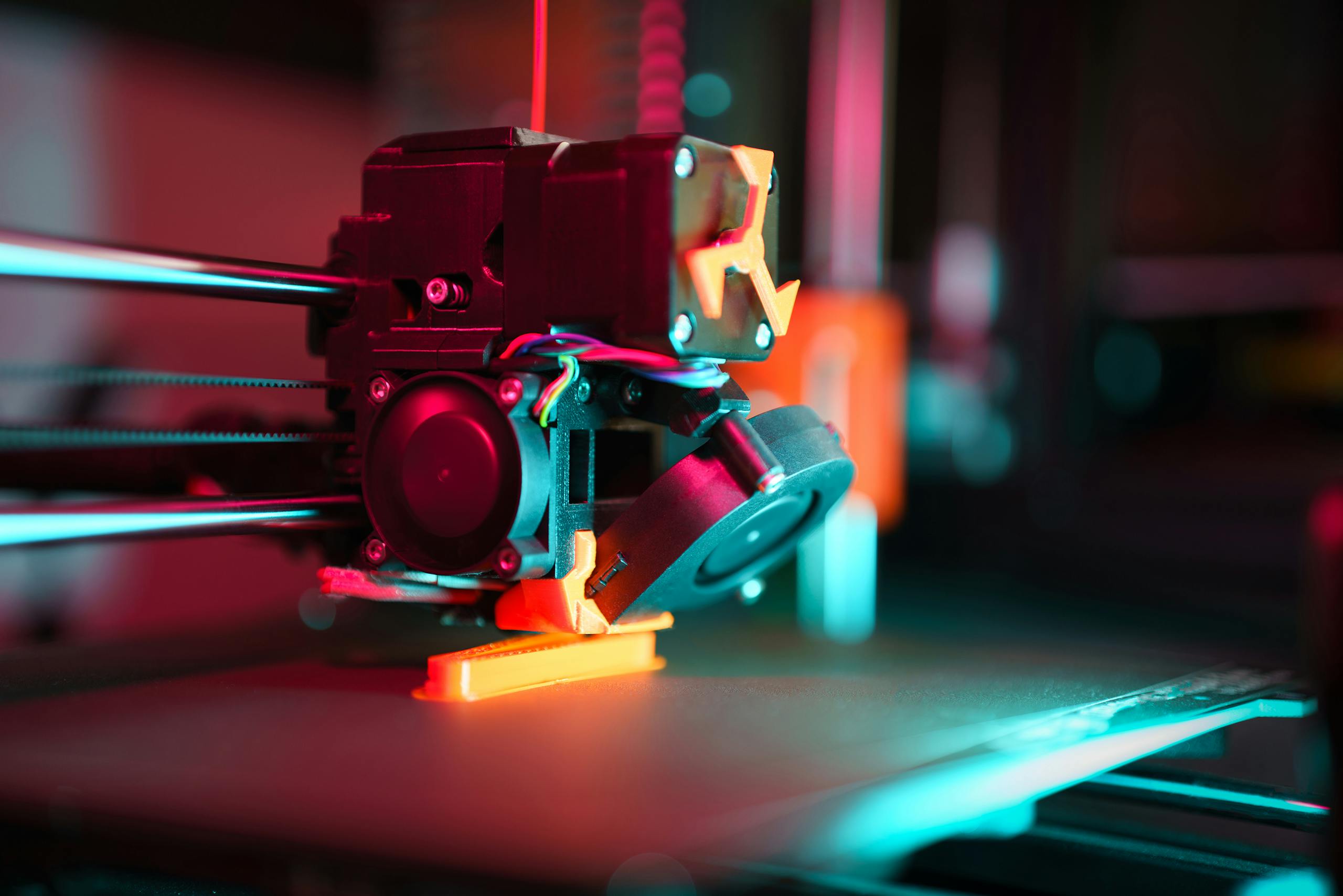

Overview of Laser Printing

Laser printing involves using a laser beam to transfer powdered toner onto the printing surface. This method is highly precise and can produce detailed images and text, making it ideal for fine markings.

The process starts with a laser scanning across a drum to create an electrostatic image. Toner particles are attracted to the drum and then transferred onto the material, often paper or plastic. Heat is applied to fuse the toner onto the surface.

Laser printing is fast and efficient, suitable for high-volume production. It also requires less cleanup compared to other methods, as it does not use liquidink. This makes it a cleaner option, especially for indoor settings.

Overview of Screen Printing

Screen printing uses ink pressed through a mesh stencil or screen to transfer an image onto the printing surface. A squeegee is used to push the ink through the open areas of the stencil.

This technique is commonly used for printing on fabrics, ceramics, glass, and other materials. It excels in producing vibrant colors and can handle various materials including dark fabrics, thanks to its opaque base layer.

Screen printing involves more setup time, as each color requires a separate stencil. However, it offers excellent color matching and is often preferred for custom clothing.

While slower than laser printing, screen printing is versatile and allows for a range of textures and finishes that are hard to achieve with other methods.

Process and Mechanisms

Laser printing and screen printing use different methods and equipment to transfer designs onto surfaces. Laser printing involves precision and speed, while screen printing relies on a stencil and mesh system.

Laser Printing Process

Laser printing uses a focused laser beam to remove or oxidize a layer of the surface material. This method is highly precise, making it ideal for small text, intricate graphics, barcodes, and logos.

Laser marking is fast because it requires minimal setup and cleanup. Once the machine settings are calibrated, the process involves directing the laser beam onto the material to create very fine and permanent marks.

Laser marking equipment can be expensive, but it requires fewer materials and less manual labor than traditional screen printing.

Screen Printing Technique

Screen printing, also known as silkscreen printing, uses a stencil (or screen) to apply ink onto a flat surface. The stencil is created using a mesh screen coated with emulsion. Where the emulsion is exposed to light, it hardens. The non-hardened parts wash away, leaving a screen with unblocked areas through which ink can be applied.

This technique is excellent for creating colorful designs. Screen printing inks are thick, providing vibrant and opaque colors, especially on darker fabrics.

The setup process for screen printing includes preparing the screen and mixing inks, which can be time-consuming. Each color requires a separate screen, making it more complex for multi-color designs.

Screen printing is suitable for producing designs in bulk, but it typically takes longer than laser printing due to the preparation and cleanup involved.

Materials and Equipment Compatibility

Laser printing and screen printing have distinct uses based on the materials they work best with and the equipment needed for each process. These factors greatly impact the suitability and efficiency of your printing projects.

Suitability for Different Materials

Laser printing is highly versatile and can work onmetals, ceramics, glass, and various plastics. The precision of laser beams allows for detailed andpermanent markings on materials like stainless steel and nylon.

Screen printing is often used for textiles such as nylon and polyester, but it can also be applied to some plastics and glass. However, it may not produce consistent results on harder surfaces like metals or ceramics.

Laser printing:

- Metals (e.g., stainless steel)

- Ceramics

- Glass

- Plastics

Screen printing:

- Textiles (e.g., nylon, polyester)

- Plastics

- Glass

Equipment Requirements and Setup

Laser printing requires specialized equipment, such as a CO2 laser marking machine. These machines are high-precision tools but are generally expensive. The setup is straightforward, often involving software to program the desired markings, making it quicker in terms of prep and cleanup.

Screen printing requires screens, inks, and a printing press. Calibrating the equipment to achieve precise markings can be challenging and time-consuming. This process involves more hands-on work, such as designing and making the screens, and is usually more labor-intensive.

Laser printing equipment:

- CO2 laser marking machine

- Software for design and programming

Screen printing equipment:

- Screens

- Inks

- Printing press

Quality, Precision, and Detailing

When comparing laser printing and screen printing, you’ll find differences in quality and precision. Each method brings unique strengths for creating detailed designs and intricate patterns.

Achieving High-Quality Outputs

Laser Printing:

Laser printing excels in producing super-saturated colors and sharp images. This method uses toner or process inks that are fused onto the material. The result is vibrant and long-lasting images. However, on fabric, the colors might leak through slightly, especially on darker textiles.

Screen Printing:

Screen printing is known for matching exact colors with ease. It applies ink through a stencil onto the fabric, offering highlydurable and resistant designs. This method is versatile and works well withvarious materials, providing consistent results in color and quality.

Detail and Precision in Printing

Laser Printing:

Laser printing offers exceptional precision and control, making it ideal for intricate logos and subtle elements. The laser beam allows for ultra-fine processing, ensuring that even the smallest details are accurately reproduced. This technique is perfect for detailed images and fine text.

Screen Printing:

Screen printing may not match the ultra-fine precision of laser printing but excels in versatility. It can print on larger surfaces faster and is great for bold and bright logos. Screen printing may struggle with super-detailed designs but excels in creating solid colors and patterns across different fabrics.

Both methods have their strengths, and the choice depends on the specific needs of your project.

Economic and Production Considerations

When deciding between laser printing and screen printing, it’s essential to look at the economic and production aspects. Key factors include upfront costs, labor expenses, production speed, and overall efficiency.

Analyzing the Costs

The initial investment in laser printing equipment is often higher than for screen printing. Laser printers require advanced machinery that can be expensive but offer precise marking capabilities.

Screen printing setup costs are lower, requiring screens, inks, and a printing press. Yet, the cost of labor can add up because it involves more manual steps.

Laser printing benefits from lower running costs. There is no need for consumables like inks and screens, making it more cost-effective in the long run.

Production Speed and Efficiency

Laser printing usually offers a faster production speed. Once the design is set, the printing process is quick and requires minimal human intervention, boosting efficiency.

Screen printing can be time-consuming, especially for multicolor prints. Each color layer needs drying time, and the setup can take longer. This makes screen printing less efficient for high-volume jobs.

For environmentally friendly considerations, laser printing produces less waste since there are no excess inks or screens to dispose of, unlike in screen printing. This can also affect long-term costs and overall efficiency.

Durability and Longevity

Laser printing and screen printing each have their strengths. When it comes to durability and longevity, both methods offer unique benefits based on how they interact with the material.

Endurance of the Printed Materials

Laser printing uses high-powered laser beams to create permanent marking on various surfaces. This method is incredibly durable because the laser etches into the material itself, resulting in marks that can withstand wear and tear. Laser prints are resistant to fading, moisture, and scratches, making them a strong choice for items that require a long-lasting finish.

Screen printing, on the other hand, involves forcing ink through a mesh screen. It produces vibrant colors and can be applied to numerous materials, such as paper, fabric, and plastic. The layers of ink used in screen printing provide an added level of strength and can handle a lot of physical stress. However, over time, especially with frequent washing or heavy use, the print might start to crack or fade.

In terms of endurance, the choice between laser printing and screen printing depends on your specific needs. For detailed, permanent marks, laser printing is superior. For colorful designs on varied substrates, screen printing holds its ground, though it may not last as long under harsh conditions.

Color and Design Aspects

In the comparison between laser marking and screen printing, important factors to consider are how colors and designs are handled in each method. Different techniques offer various strengths in color vibrancy,color matching, and design complexity.

Color Vibrancy and Matching

Screen printing is excellent for vivid color vibrancy. This method uses inks that are directly applied to the material, allowing for bright and bold colors.Multicolored patterns can be easily achieved by layering different colors like cyan, yellow, magenta, and green. This method excel in accurate color matching, making it ideal for designs where precise colors are crucial.

Laser printing, on the other hand, typically uses process inks or color gamuts. This means the range of colors might not be as broad, leading to potential issues in matching the most vibrant shades. Despite this, laser printing ensures uniformity in each print, which is useful for maintaining consistency across large batches.

Complexity of Designs and Patterns

Screen printing is highly effective for simpler designs and larger areas of solid color. Complex or intricate patterns can be a challenge, particularly when layering multiple colors. Doing so can lead tocolor bleed, especially on dark fabrics, resulting in less precise lines. Thus, designs requiring distress effect or fine details may be harder to achieve with screen printing.

Laser marking stands out in its ability to produce intricate and precise designs. This method uses a laser to remove a portion of the material, allowing for fine details, including text, graphics, and barcodes. Laser printing handles tiny marks and small components better than screen printing. Additionally, it’s faster at producing designs, making it ideal for high-volume production with fine details.

Environmental and Safety Factors

Laser printing and screen printing have distinct impacts on the environment and safety. Understanding these differences can help you make more informed choices.

Eco-Friendliness

Laser printing is often considered environmentally friendly. It uses no inks or solvents, reducing emissions. Laser marking is also precise, minimizing waste. You don’t need to worry about the disposal of hazardous materials.

Screen printing, particularly with plastisol inks, can be less eco-friendly. These inks contain PVC and phthalates, which are harmful to the environment. Water-based inks are a better option, but they still require water for cleaning, which can cause water pollution.

Safety

Laser printing is safer for workers due to less exposure to harmful chemicals and fewer safety hazards. It’s cleaner, as there is no ink spillage or solvent inhalation.

Screen printing involves more safety risks. Workers can be exposed to fumes from inks and solvents, posing respiratory issues. The handling of heavy screens and chemicals can also cause physical injuries. Proper ventilation and protective gear are crucial in these settings.

Advantages and Disadvantages

Laser and screen printing each have their unique pros and cons that make them suitable for different applications. The choice between the two often depends on factors such as the level of detail required, the type of material, and the cost.

Pros and Cons of Laser Printing

Pros:

- Precision: Laser printing offers high precision, allowing for detailed images, text, and graphics. This makes it ideal for intricate designs.

- Durability: The process etches the design onto the material, making it highly resistant to wear and tear. The design won’t rub off easily.

- Flexibility: It works on various materials, including metal, plastic, and glass. This makes it versatile for different products.

- Speed: Especially useful for high-volume production lines, laser printing can efficiently handle large batches.

Cons:

- Color Limitations: Laser printing struggles to match the vibrant colors that screen printing can achieve. The colors may appear less vivid.

- Cost: The initial setup and equipment costs for laser printing can be high, making it less accessible for small-scale operations.

- Surface Restrictions: Not suitable for very soft or uneven surfaces. It works best on hard, flat surfaces.

Pros and Cons of Screen Printing

Pros:

- Vibrant Colors: Screen printing excels at producing bright and bold colors, making it perfect for eye-catching designs.

- Versatility: Works on a wide range of materials, including fabric, metal, paper, and plastic. This flexibility is a significant advantage.

- Durability: The inks used are durable and withstand repeated washing and exposure to various elements.

- Cost-effective: For large batches, screen printing can be more economical, as the cost per unit decreases with scale.

Cons:

- Detail Limitation: It’s not as precise as laser printing. Fine details and small text may not come out well.

- Time-consuming: The process can be slower, especially for multi-color designs requiring multiple screens.

- Messy Setup: The setup involves inks and screens, which can be cumbersome and messy. Cleanup can also be labor-intensive.

- Opacity Issues: On darker fabrics, the base color might leak through, affecting the final output.

Applications and Industry Use

Both laser printing and screen printing have unique applications in various industries. Depending on the needs, one might be more suitable than the other for specific tasks.

Industrial and Commercial Applications

Laser printing excels in high-volume production environments. This technique is often used for industrial marking, such as etching bar codes on metal surfaces or marking packaging materials. The precision of laser processing allows for fine details, which can be vital for logos and other detailed graphics.

The process also has sanitary benefits, as it can be acleaner option, reducing the need for harsh chemicals. It is often managed by computer software, allowing for easy programmed patterns and adjustments.

Screen printing, on the other hand, is highly favored in the textile industry. It can be used for direct-to-garment printing on various fabrics, including dark garments. This method allows for vibrant colors and intricate designs that can stand out on textiles of any color, ideal for logos or promotional materials.

Specialized Applications and Customization

Laser printing is often chosen for creatingcustomized items. Its ability to etch designs onto small parts with high precision makes it perfect for specialized applications. This includes markingelectronics, tools, and other items requiring detailed identification marks.

In more artistic applications, laser printing can produce programmed patterns that would be challenging to achieve with other methods. This technology offers flexibility and speed, crucial for producing unique designs on metals and plastics.

Screen printing is suitable for creating custom promotional items and special event merchandise. It’s capable of producing multicolored patterns through a process called simulated process printing. This is especially useful for creating detailed images and logos in high quantities for events, trade shows, and marketing campaigns.

Frequently Asked Questions

This section will address thecost implications,fabric applications, and durability comparisons of laser and screen printing. It will also cover other related questions for a better understanding of both techniques.

What are the cost implications of laser printing compared to screen printing?

Laser printing usually has higher initial costs for equipment but lower ongoing costs. In contrast, screen printing equipment might be cheaper, but the process is labor-intensive and requires more materials, impacting the overall cost.

How do laser printing and screen printing differ in terms of fabric application?

Screen printing works well on both light and dark fabrics but may suffer from color seepage. Laser printing offers high precision but is typically less vibrant on darker fabrics and might not match every shade accurately.

What are the key differences between laser printing and pad printing techniques?

Laser printing involves no direct contact with the material, resulting in cleaner prints. Pad printing, used for irregular surfaces, involves a pad that transfers ink, making it suitable for products like mugs and pens but less precise than laser printing.

In what ways do laser engraving and laser printing differ for material processing?

Laser engraving removes material to create a design, suitable for durable markings on metal and wood. Laser printing, on the other hand, uses toner or ink to create surface designs, often used fortextiles and paper but not for deep cuts or engravings.

Can laser printers be used in the process of screen printing preparation?

Yes, laser printers can create high-quality stencils or screens for screen printing. You can use a laser printer to print designs on transparency film, which is then used to expose the screen for your screen printing project.

How does the durability of prints from laser and screen printing compare?

Laser printing generally provides longer-lasting designs, especially on hard materials. Screen printing is durable on fabrics but may fade with frequent washing. Laser marking is more resistant to environmental factors, making it suitable for items exposed to harsh conditions.